Hanging out my shingle

I recently became registered as a professional engineer with APEGNB so it seemed like a good time to write a post describing what I do in my job, which is in the field of industrial wastewater treatment.

The company I work for provides wastewater treatment systems (typically via design-build delivery) for industrial customers such as dairy plants, breweries, and other food & beverage processors, pulp & paper plants, distilleries, biofuels producers, and more. These types of wastewaters are typically suitable for biological treatment processes (either anaerobic or aerobic).

People more commonly think of municipal wastewater treatment plants (WWTP), and small industrial facilities can often discharge to the public sewer without difficulty. However, larger industries (or those located remote from any public facilities) may be required—or find it advantageous—to put in on-site treatment for their own wastewater. This can include pre-treatment to reduce the load on the public WWTP, or a system configured for direct discharge if they need to avoid the public sewer entirely. Motivating factors for industrial facilities to install or upgrade on-site wastewater treatment systems include:

- Tightening environmental regulations, including nutrient limits.

- Rising fees or surcharges for using the public sewer.

- Avoiding lost production time from wastewater treatment going down (i.e. controlling this risk).

- Wanting to recover energy (in the form of biogas) or treated water for reuse.

Some of my professional interests include:

- Treatability / biochemical methane potential (BMP) testing

- Process modelling for nutrient removal applications

- Wastewater-to-energy opportunities

- Water reuse

Day-to-day, I do things like writing proposals, reports, design & operation manuals, going out in the field for process start-ups and follow-up, and being involved in some pilot-scale or laboratory studies.

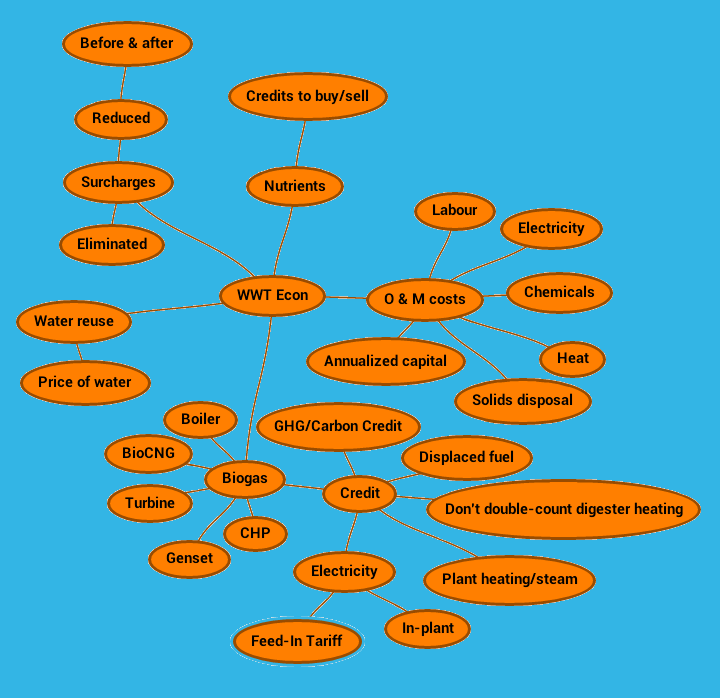

I made this mind-map around some of the things that go into the economics of running an industrial wastewater treatment system (both costs and possible benefits/savings). Anyone looking at getting such a system should look beyond just the initial capital cost and this graphic can be a good starting point. Another important factor to consider is reliability—you definitely do not want to lose any valuable production time due to problems with wastewater treatment.

If you're interested, here are some previous posts on my blog that are relevant to industrial wastewater treatment for further reading:

- GHOST_URL/weftec-2014/

- GHOST_URL/open-access-journals-for-water-and-wastewater/

- GHOST_URL/asm1-in-octave/

- GHOST_URL/water-and-wastewater-vocabulary-in-arabic/

- GHOST_URL/water-energy-nexus/

- GHOST_URL/2015-industrial-and-commercial-water-reuse-conference/

- GHOST_URL/weftec-2015/

A final thing to keep in mind is that good wastewater treatment can be expensive, but not nearly as expensive in the long run as bad wastewater treatment.

If you want to connect regarding this topic, find me on LinkedIn.