Fixing my 3d Printer

As I mentioned in an earlier post, my 3D printer needed a new hot end. It took longer than I was expecting, but I finally got it installed.

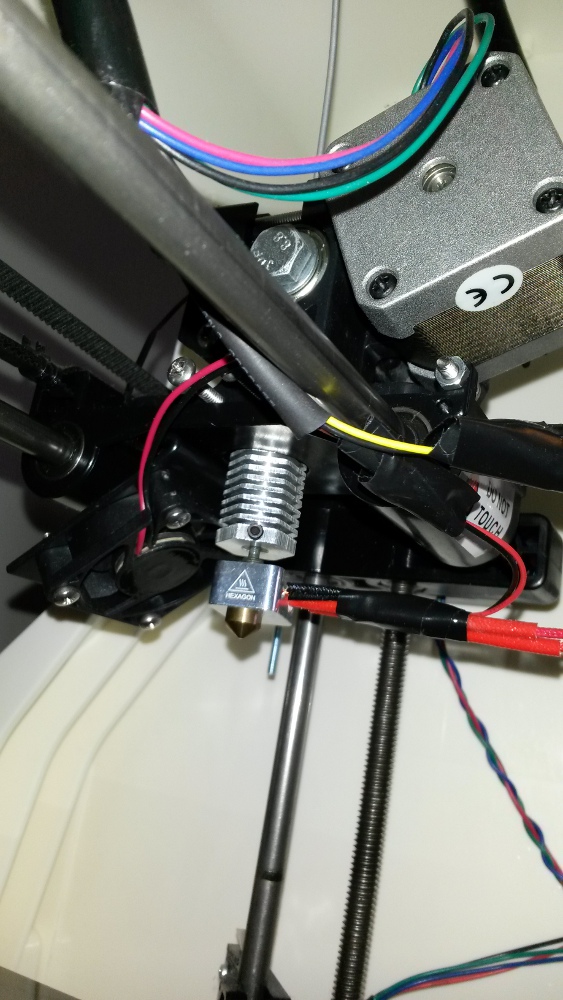

I got a Hexagon hot-end, which is different from the stock hot-end on my Robo3D R1 printer. The "hot-end" is the part of the 3D printer that heats up the plastic (PLA in my case) filament fed into it enough that it can be extruded through the fine nozzle (0.4 mm) at the tip.

The hot-end includes a heater cartridge and a thermistor for temperature feed back to the controller. To get a good electrical connection, I had to solder some of the wires, which is not something I'm very practiced at.

The new hot-end is shorter than the old one, so it was a tight fit. I'm a little concerned that the position of the fan will not get good air flow over the cooling fins, but I wanted to get printing again rather than spending more time working on the printer so I didn't try to adjust it. The shorter hot-end also required adjusting some screws that contact the axis endpoint detectors so that the servo motors would stop at the proper place.

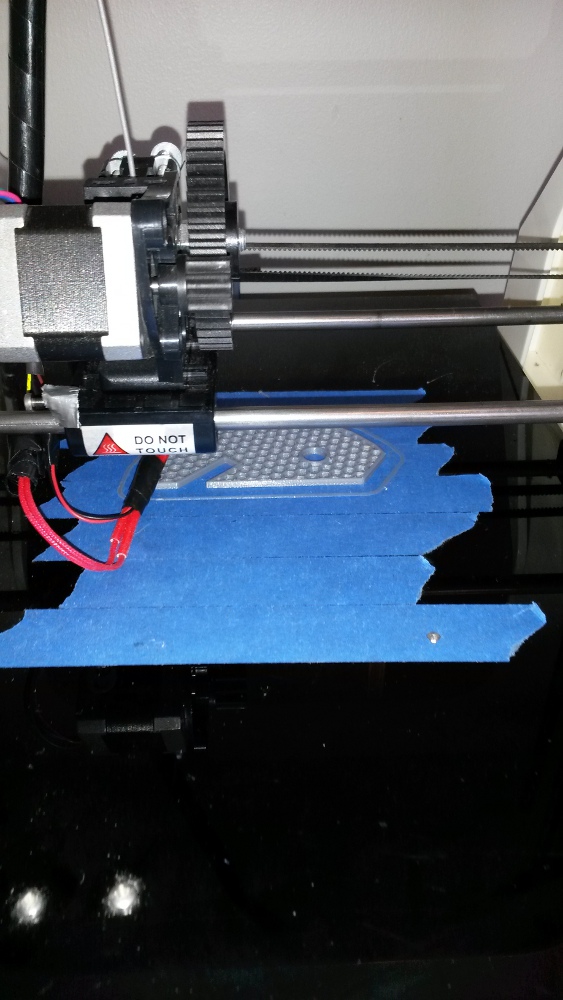

My first test print worked very well. The printer did jam up on the second print I tried, though. I hope it can keep working, because I have a back-log of printing project ideas (some of which I may blog about). The 3D printer that I have has been good for learning about the technology, and it was quite easy to access the hot-end component to change it out (other than the wiring which required wire cutters and strippers, and a soldering tool, the only thing I needed was a screwdriver). However, going forward I'd like it to just work, as I'm much more interested in 3d printing stuff than in modding the printer. At least if I doesn't work I can use 3D printing services.