Materials, Processes, and Supply Chains: Recent Readings on Technology and Industry

steel, silicon, jet engines, microchips, cars, phones, paper, and pipe organs

A collection of mini-reviews, all on my reading theme for 2024; for other books I read last year see my other mini-review post.

This post is the culmination of a goal I had last year to read several books on the theme of industrial production and adjacent topics such as technology and supply chains. These are the six books:

- Material World by Ed Conway

- The Perfectionists by Simon Winchester

- Paper by Mark Kurlansky

- Connectography by Parag Khanna

- From The Garden to The City by John Dyer

- A Culture of Improvement by Robert Friedel

These relate to the theme from different perspectives. Material World is a global tour of the processing and products of some of the most fundamental materials in our current economy. The Perfectionists explores the historical development of ever-finer precision in manufacturing. Paper is the history of a single industry. Connectography has to do with supply chains, infrastructure, and the geopolitics associated with them. From the Garden to the City covers some theological and ethical considerations around technology. Finally, A Culture of Improvement is a longitudinal history of technology and innovation in the West.

Material World would be my top recommendation for a general audience. The Perfectionists is very well written (it's not the first book I've read by Simon Winchester, and I'm planning to read another one of his next year) but its appeal may be more niche—definitely recommended for engineers and anyone with a passion for mechanical things. A Culture of Improvement would make a good basis for a history class (e.g. if you're home-schooling a high schooler with an interest in technology) because it surveys a thousand-year span of history, and developments in technology frequently touch on other things that were going on. From the Garden to the City is recommended if you're a Christian and want to be thoughtful and deliberate in the way you and your family use technology. Paper was alright, but I've read another book by Mark Kurlansky (Salt) and it was better. Connectography I found didn't really offer enough ideas to justify reading the full book; finding a magazine article or podcast appearance by the author would probably be a better use of your time if you're interested in its content.

As should come as no surprise, considering it covers six books, this is a very long post. Unlike posts where I just cover one or two books, I haven't tried to write full reviews. Instead, for each book I have a section below where I share some excerpts that stood out followed by point-form notes on other key points. At the end of this post, I have a section where I bring together some recurring concepts that I noticed from reading multiple books related to this common theme. I'd suggest readers just skim a section or two from whichever book(s) sounded the most appealing in the previous couple of paragraphs, then jump down to the final section where I try to highlight my most notable take-aways.

Material World

The dematerialization debate is something I've discussed before (e.g. in this post). Material World is about the parts of our modern industrial economy that are still material-intensive, and about how much we depend on them.

For all that we are told we live in an increasingly dematerialised world, where ever more value lies in intangible items—apps and networks and online services—the physical world continues to underpin everything else. This is not especially evident when you glance at the balance sheets of our economies, which show that, for instance, four out of every five dollars generated in the U.S. can be traced back to the services sector and an ever vanishing fraction is attributed to energy, mining and manufacturing. But pretty much everything from social networks to retail to financial services is wholly reliant upon the physical infrastructure that facilitates it and the energy that powers it. Without concrete, copper and fibre optics there would be no data centres, no electricity, no internet. The world, dare I say, would not end if Twitter or Instagram suddenly ceased to exist; if we suddenly ran out of steel or natural gas, however, that would be a very different story.

The author identifies 6 materials (or categories in a couple of cases) that are vital to our civilization yet often taken for granted. These are listed as subcategories below.

Material World is also a book about global supply chains. This was very relevant in the aftermath of the pandemic and is even more so now in 2025 in the midst of tariff/trade disputes. Ed Conway describes how supply chains create networks of people who don’t know each other but yet can work together to make something useful:

These networks of people and expertise, turning raw materials into sophisticated products and then delivering them to us, stand alongside the substances themselves as the other star of this book. In the following pages you will find a celebration of how networks of humans, most of whom do not know each other, can collaborate to turn seemingly unpromising, inert substances into things of wonder.

He refers to the well-known essay "I, Pencil" on this topic.

Another thing from the introduction that stood out to me was where he says he looked into why gold was (briefly) one of the UK's biggest exports. I had wondered the same thing while writing this post and apparently the answer is: "As far as I could make out, part of the answer was that much of the world’s physical gold passes through London on its way somewhere else."

Material World is divided into 6 sections, on: sand (incl concrete and silicon), salt(s), steel, copper, petroleum and plastics, and lithium. I'm going to share some interesting facts and notable processes from each of these sections, and then some overall takeaways from the book.

Sand

The section on sand has a lot of overlap with a book about sand that I read several years ago. However, I'd say Material World covers it better. The thing about sand is that it is such a commonplace material but some of its uses are very strategic. Aside from semiconductors, which I'll focus on in this section, other uses of sand include land reclamation, as a component of concrete, and for glass, including lenses and fibre optics.

Conway brings readers along as he follows the global supply chain for semiconductors:

Between being blasted out of the ground in a quarry and ending up inside a smartphone, this grain of silicon will have circumnavigated the world numerous times. It will have been heated to more than 1,000°C and then cooled, not once or twice but three times.

I mapped out the route he took in Google Earth (see the following screenshot):

- Ferroglobe mine in Galicia, Spain

- Wacker in Burghausen making polysilicon

- Shin Etsu in Vancouver WA making large boules/ingots that are single crystals of silicon

- TSMC, south Taiwan

- Malaysia, adding wiring

- China, final assembly of electronics

While TSMC might be approaching a household name these days, a lot of the upstream suppliers are not. Of course, tracing the path the silicon takes is not the only part of the supply chain. There are the photolithography machines from ASML in the Netherlands (which themselves use optics from Zeiss in Germany), special quartz crucibles from a couple of special mines in North Carolina, specialty chemicals, and more.

Why does this supply chain span the globe? For cutting-edge chips (Intel's 4004 back in 1971 had 2,000 transistors while current chips have over 12 billion!), ten 9's of purity are needed. With that little room for error, it's necessary to use the best supplier at every stage: the best quality silica sand to start with, the best processing techniques, the best photolithography equipment. This processing is also highly energy-intensive:

According to scientist Vaclav Smil, the energy cost of ultra-pure silicon such as this is more than 3,000 times that of cement and 1,000 times that of turning iron into steel.

These chips have become a highly strategic item:

As Morris Chang put it in 2019, “As the world is no longer peaceful, TSMC is gaining vital importance in geostrategic terms.”[7] And the scale of this reliance is greater than you might imagine. China spends more money on importing computer chips these days than it does importing oil. Indeed, according to Chris Miller, the author of a history of silicon chips, China’s semiconductor import costs as of 2017 were greater than Saudi Arabia’s total revenue from oil exports, or for that matter the entire global trade in aircraft.

Conway draws parallels to the lengths countries went to to acquire rifle scopes and binoculars (also made by Zeiss, he points out) in WW1:

For most of our lives we can safely assume that a given item, whether it is a pair of binoculars or a semiconductor or a lump of base metal, can be easily sourced from one part of the world or another. But every so often a catastrophe, be it a war or a pandemic or an unfortunate ship getting jammed in the Suez Canal, forces us to think twice.

While I've mainly focused on semiconductors in this sub-section, I did want to briefly touch on concrete. I learned that there are 80 tonnes of concrete per person in the world. And its availability can make a big difference. Conway recounts that Mexican families switching from dirt floors to concrete floors experienced a 78% drop in parasitic infections. This relates to what he outright labels as a "recurring theme" (emphasis added):

The ability to produce vast quantities of a given substance might not capture the imagination, but it is another of the recurring themes one encounters as one tours the Material World. From concrete to copper, from iron to lithium, it is our ability not merely to invent the future but to mass produce and disseminate these materials that has enhanced lives and lifted millions from poverty. To put it another way, the reason cement has changed the world is not merely because it has magical qualities but because it is cheap and it is everywhere.

Salt(s)

The section of Material World on salt had a lot of overlap with the book by Mark Kurlansky of that name. So I'll skip the historical material in this mini-review.

Something that stood out to me from this section was how enduring or "sticky" the legacy of salt extraction is to the present day in terms of where chemical companies are located. There's a lot of path-dependence in clusters of infrastructure and skills:

Look at the map of the world’s pharmaceuticals and chemicals companies, and you see that we are still following ancient salt routes. In Britain these chemicals and drugs firms are still located next to salt: some atop the slab of halite in Cheshire, others in Teesside where we used to extract salt. It is not for nothing that American chemicals giant Dow is headquartered in Michigan, above those deep rock-salt formations that sit beneath Detroit. As the trucks come and go with chemicals and pharmaceuticals, they are essentially retracing the same ancient salt routes as our ancestors.

Aside from NaCl, this section covers other salts (like nitrates and potassium compounds) used for fertilizers and munitions. Before the invention of the Haber-Bosch process that made synthetic nitrogen fertilizers commonplace, nitrates were so sought-after that a war was fought among Chile, Bolivia, and Peru for access to deposits of them.

This section also covers important chemical processes that use salt as an input:

- The Chloralkali process is used to make caustic soda and chlorine ("one of those chemicals that is both lifesaving and life-threatening in more or less equal measure")

- The Solvay process is used to make soda ash

These products are in turn inputs to all sorts of other processes that make modern civilization possible. Not the least of which, in my view, being water and wastewater treatment. Note that the Haber-Bosch and Chloralkali processes are very energy-intensive.

Steel

Here are some things that I learned or that stood out to me in the section on iron and steel:

- Good metal tools save labour: the minutes of work to yield a kilogram of grain dropped 14x in 19th C. (so before outright mechanization of agriculture), partially from metal tools replacing wood tools

- There are 15 tonnes of steel per person in the developed world (in structures, vehicles, tools/equipment, infrastructure, etc.)

In stark contrast to those rich-world levels of 15 tonnes per person, the average person in China today has roughly 7 tonnes of steel. The average person living in sub-Saharan Africa has less than a tonne of steel per capita.

- Now, China makes more steel in 2 years than the UK has in its history

- Hittites started smelting iron circa 14th C. BC

- Conway refers to the paradox of steel’s importance: because it has become so cheap, it doesn’t show up as a huge percentage of GDP

Here we run smack bang into the same lesson we learned from concrete: what makes steel a mainstay of the Material World? Not merely that it is very good at doing what it does, but that it is both very good and very cheap. That cheapness—which means steel is a vanishing part of our GDP statistics—is its secret weapon.

- He mentions that the largest CO2 emitter in UK was a steel mill, the Port Talbot facility. As I was reading Material World, the closure of the blast furnaces there was announced. As I've been writing this review, the last blast furnace in the UK, at Scunthorpe, was also going to be shutdown, although at the moment the government has taken over operation to prevent this.

indeed, since steel production is dirty and energy intensive, wealthy countries are in the habit these days of closing down steel mills, reducing their domestic production and importing the finished product from countries where carbon emissions are not quite so controversial.

Letting steel refining go overseas reduces local pollution and gets emissions off the books. However, it introduces some supply chain vulnerability that a lot of leaders are suddenly waking up to.

How is iron processed into steel?

- A blast furnace makes pig iron from iron ore, coke, and flux stone

- In a basic oxygen furnace (a modern evolution of the Bessemer process), the carbon content of pig iron is reduced to turn it into steel

- Once steel is made, it may go through alloying and then hot rolling

- Electric arc furnaces are used to recycle steel but can't make virgin steel the way blast furnaces can

- The Direct Reduced Iron process is a new alternative to blast furnaces, and one of the promising parts of the hydrogen economy (in stark contrast to fueling passenger vehicles), in my opinion

Copper

Conway calls copper “civilization’s nervous system”. It's main and most important application is conducting electricity. As the world attempts to electrify more sectors (most obviously transportation) the demand for copper is likely to keep increasing.

Copper is the great, unseen substrate that supports the modern world as we know it. Without it, we are quite literally left in the dark. If steel provides the skeleton of our world and concrete its flesh then copper is civilisation’s nervous system, the circuitry and cables we never see but couldn’t function without.

Apparently the average car contains around a mile of copper wire, and electric cars are well above this amount.

One crucial use of copper wire is in windings. If a long wire is coiled up compactly with the right geometry, it can make current (or otherwise convert between electricity and magnetism). I find it fascinating that simply arranging a single element–and copper used for electrical purposes is very pure, to the extent that only electrolytic refining is good enough for the final processing step–into a special shape can be so useful.

These tangled webs of copper are the workhorses of modern life, for they are where the vast majority of the world’s power is generated.

Because copper is in high demand but its ore deposits are typically low-purity, copper mines are some of the largest in the world. A couple that are discussed in Material World are Bingham Canyon and Chuquicamata.

After it is mined, copper needs to be smelted. This requires a lot of energy. Swansea in Wales gained the nickname "Copperopolis" because of how much copper was smelted there, despite not a lot of it being mined in the vicinity. This is because Wales had plentiful coal deposits and it made more sense to bring the copper to the coal than vice versa. Material World points out that China has adopted this model–not just for copper but for many metals–of importing ore and then exporting processed metal. Although China also imports energy, so they've gone a step further than the Swansea approach.

Today, China is the world’s processer-in-chief, smelting and refining nearly half of the world’s supply of copper

Petrochemicals

The section on oil & gas in Material World covers two applications: energy, and as a feedstock for materials. One of the inescapable facts about materials processing is that it is very energy-intensive:

The vast majority of processes you have encountered in the preceding pages, from the transformation of sand into glass, through to the creation of silicon chips, the production of chlorine out of brine, the conversion of iron into steel and the generation of electricity, depends on enormous amounts of energy, most of which is currently delivered to us, directly or indirectly, by fossil fuels.

However, there's a whole petrochemical industry beyond just the use of oil & gas for energy. Germany, for example, has tons of coal while lacking other natural resources. But their chemical engineers figured out how to use it as a feedstock for a diversified chemical industry, even surprising things like dyes and drugs. Later, the ability of their refineries to make liquid fuels from coal kept their planes and tanks going in WW2:

But what Germany lacked in natural resources it more than made up for with its scientists, the most disciplined and ingenious in the world, capable of turning coal into pretty much everything. While Britain and America built their early chemicals industries out of salt, Germany deployed coal and alchemy. Pharmaceutical giant Bayer had made millions by turning German coal into acetylsalicylic acid, a drug better known as aspirin. BASF had made millions by turning German coal into an extraordinary range of dyes. Turning German coal into a gasoline that could be used in tanks, trucks and planes was, in the circumstances, simply the next logical step.

Plastics are byproducts of oil refining (and there’s an interesting story in how marketing was used to create demand so they didn’t have to be wasted, i.e. flared). They’re cheap because of the demand for gas and diesel. Material World has plenty to say about the widely-used polyethylene. Other plastic families include styrene, polypropylene, nylon, vinyls (like PVC), and epoxies (“thermosetting”):

Polyethylene isn’t the only plastic—indeed it’s one of five main families of human-made polymer. There is polystyrene, famed for its puffy packaging foam but equally capable of being moulded into a hard, clear plastic. There is vinyl—polyvinyl chloride—from which you can make hard pipes or soft shower curtains. There is nylon, famed for its silky stockings but just as easily moulded into hard machine screws. There is polypropylene, flexible enough to be used as the lid of a flip-top bottle but hard enough to be formed into furniture. There are also thermosetting materials like epoxy resin, most familiar to us as a glue but even more important as a binding matrix that helps carbon fibre and fibreglass set into ultra-hard materials.

Something that stood out to me is that this section has a whole chapter called simply “Pipes”—it makes the point that refineries are a bewildering maze of pipes and vessels but effect the remarkable transformation of crude into a host of useful products.

Finally, a couple of facts that are notable in light of current trade disputes ("tug-of-war" as Connectography, reviewed below, would have it):

- "long after China became the world’s biggest manufacturer it was still importing most of its raw plastic from sites in the West. But since 2010 that has begun to change. Today, a third of the world’s raw plastic is made in China"

- The scale of some oil & gas facilities is simply enormous. I noted in this post that it's feasible to comprehensively list refineries around the world; they are very strategic nodes in global supply chains. According to Conway, 4% of global energy flows (not sure if he just means what is traded internationally?) pass through a single port in Qatar: Ras Laffan

Lithium

Of the six categories of materials in Material World, the most recent to rise to prominence is Lithium. This is because it has useful chemistry for batteries. Electric cars are the quintessential users of lithium-based batteries (the battery is the expensive part, like the engine in an ICE car), and have contributed to a steep rise in demand for it:

A typical electric car battery contains about 40kg of lithium, alongside 10kg of cobalt, 10kg of manganese and 40kg of nickel. This is before you consider the graphite that goes into the anode. These materials have to come from somewhere, of course, and the race to procure them is accelerating.

The section on lithium goes from deposits in the Atacama desert in South America to a tour of a Tesla Gigafactory. The factory is split between Tesla and Panasonic. Interestingly, there is a legacy of cassette/VCR companies in producing these types of batteries because they get wound up like jelly rolls. The Gigafactory is far ahead of other companies in its battery output; however, 80% of global production of lithium batteries is in China.

One of the challenges with moving to batteries is that their energy density is much lower than liquid fuels; this is partially offset by batteries being multi-use (rechargeable, and later recyclable). On top of this, the countries with reserves aren’t totally comfortable with mining it:

this time there are three important differences. The first is that this time around we are moving down the energy ladder rather than up it. Lithium-ion batteries are significantly less energy-dense than oil, gas or even coal. The second is that the materials we are mining are not being burned; their power is not being vaporised but installed inside batteries, which could, in theory at least, be recycled. The third is that the countries doing the extraction are no longer so sure that they want to do it any more.

Conway gives a reality check that electrification of transportation and other sectors won't be easy:

For decades we have convinced ourselves that the main constraint facing humanity is the scope of our imagination. We created an economic system so sophisticated and seamless that it allowed us to forget about the materials upon which it was built. But in attempting to build our way to net zero, we are confronting the inescapable limitations of thermodynamics and material constraints.

Moving past looking at these materials individually, Material World has some overall conclusions that are worth discussing. A theme that permeates the book is that we’ve forgotten the material foundations of our economy because that sector has gotten so efficient with labour:

As the fruits of the Material World have become ever cheaper, they have come to account for an ever smaller fraction of our national expenditure, with the result that they are often overlooked in conventional accounts of the economy. Try to argue that folks ought to be taking salt more seriously, that they ought to regard it not just as a trivial condiment but as a substance that makes the modern world work, and you will be met with baffled looks. I know this from personal experience

Part of the reason for things getting cheaper is Wright's Law.

Conway is trying to remind readers of the material foundations of our economy and that even things viewed as sustainable such as renewable energy will require large inputs from the material world of mining and metal processing:

Consider what it takes to replace a small natural gas turbine, pumping out 100 megawatts of electricity, enough for up to 100,000 homes, with wind power. You would need around 20 enormous wind turbines. To build those turbines you will need nearly 30,000 tonnes of iron and almost 50,000 tonnes of concrete, along with 900 tonnes of plastics and fibreglass for the blades and 540 tonnes of copper (or three times that for an offshore wind farm). The gas turbine, on the other hand, would take around 300 tonnes of iron, 2,000 tonnes of concrete and perhaps 50 tonnes of copper in the windings and transformers.

I enjoyed reading this book and I'm a bit jealous of all the sites the author contrived to tour for his research.

I'll end this mini-review with reference to a site he did not tour or mention. Becancour QC has an industrial park with chloralkali and silicon plants (and also an aluminum smelter). It is located next to a nuclear reactor. This is not a coincidence. Affordable and reliable energy is key to the materials processing that is an indispensable step in strategic supply chains like those discussed in Material World.

The Perfectionists

The Perfectionists is about precision engineering; you could even say it's about the very idea of precision, its historical development, and essential role in so much of what we take for granted in modern technologies and the modern economy. It's by Simon Winchester, who's a talented writer and has lived an interesting life, from working in offshore O&G in the North Sea to being a foreign correspondent. I've read a previous book he wrote (about some of his travels in Asia). He comes by his interest in precision honestly, as his father was a passionate mechanical engineer.

The chapters are arranged chronologically, and also in order of increasing precision, from Harrison marine chronometers losing less than a second per day to modern GPS satellites keeping time to tens of nanoseconds (although these examples both have to do with time, precision in dimensions occupies more of the book). Speaking of Harrison's clocks, this really illustrates the way with words the author has:

his clocks gather dust and salt, or are kept in glass cases, and his name will begin to slip gradually astern, to vanish inevitably and soon in a sea fret of history, way stations at the beginning of the voyage.

Winchester calls precision an invention rather than a discovery:

Precision was a concept that was invented, quite deliberately, out of a single and well-recognized historic need. It was brought into being for severely practical reasons—reasons that had much to do not with any dreamy twenty-first-century wish to confirm (or otherwise) the existence of vibrations from the collisions of distant stars. Rather, it had to do with a down-to-earth eighteenth-century realization of what was then a pressing matter of physics, and which was related to the potentially awesome power of that high-temperature form of water that since the century before had been known as and defined by the word steam.

Tolerances are limits on imprecision and they are key to having parts work together (as anyone who's gotten into 3D printing can tell you):

There is precious little point in tolerance if the machined object is simply to stand upright and alone in the middle of a desert. But to fit with another equally finely machined piece of metal, the piece in question must have an agreed or stated amount of permissible variation in its dimensions or geometry that will allow it to fit.

A key element of precision, at least for it to have the economic impact that it has over the past 2 to 3 centuries, is that it must be replicable. It's not enough for a Part A to fit with a Part B; rather, any Part A must fit with any Part B. This is where machine tools had a huge advantage over hand-machining—you can still achieve a very good fit with sufficient skill, but parts won’t be interchangeable:

For precision to be a phenomenon that would entirely alter human society, as it undeniably has done and will do for the foreseeable future, it has to be expressed in a form that is duplicable; it has to be possible for the same precise artifact to be made again and again with comparative ease and at a reasonable frequency and cost.

This point about what a game-changer it is making things in quantity and at low cost comes up more than once in The Perfectionists, and also in some of the other books covered in this post.

An instance of precision that was very impressive at the time, and an important stepping stone even if it has been surpassed by now, was John Wilkinson boring steam engine cylinders to an accuracy of a tenth of an inch using a technique he developed for machining cannons.

The Perfectionists has a lot to say about Henry Maudslay. His inventions included very good screws, a method for flatness, and the micrometer. He was also involved in making machines to make pulley blocks for the Portsmouth Block Mills. Ships in that era required something like 1400 blocks each and they took 16 operations to manufacture, so being able to mass-produce them was a big win for British naval power.

In this era, education for engineers (in Britain, anyway, other books covered in this post discuss differences in other countries like France and the US) was quite informal:

The big-name turn-of-the century engineers all seemed to know one another, to train one another, to be apprenticed to one another. Whitworth was very much part of this picture. His profound interest in mechanical perfection began when he was a very young man—he had been effectively orphaned after his mother died and his father took off to train as a priest—and was apprenticed to Henry Maudslay.

There was a lot of optimism about the potential of new technologies, as exemplified by the Great Exhibition of 1851 and World's Fairs that followed it. The Great Exhibition was hosted in a building called the Crystal Palace, which had almost 1 million square feet of glass panels and was built in 6 months (hard to imagine something of this scale being built so quickly today).

I liked this poem by Tennyson that was written for the 1862 International Exhibition for its realistic view that new technologies can be used for peace or war:

All of beauty, all of use

That one fair planet can produce,

Brought from under every star,

Blown from over every main,

And mixt, as life is mixt with pain

The works of peace with works of war.

Moving into the 20th century, The Perfectionists has an illuminating side-by-side comparison of Rolls Royce and Ford. It's probably not too much of a stretch to consider some of their characteristics as being typical, perhaps, of broader differences in British and American manufacturing. Rolls Royce focused on bespoke hand construction whereas Ford became famous for the assembly line.

Yet, while Henry Royce over in Manchester had been captivated by perfection, Henry Ford in Dearborn was consumed by production. Their two fledgling companies, so similar in so many ways, each wedded to the idea of making the best and most suitable machine it could, began to diverge in both purpose and practice from the moment of their respective foundings.

The Model T saw 16.5 million units produced in ~20 years. Whereas Rolls Royce had only 8000 units in about the same length of time, just two per day, as Winchester emphasizes. He also makes a point about how vital it was to have precise and interchangeable—interchangeable as a result of being precise—parts to make mass production work:

And precision’s differing roles in the two companies? Within Rolls-Royce, it may seem as though the worship of the precise was entirely central to the making of these enormously comfortable, stylish, swift, and comprehensively memorable cars. In fact, it was far more crucial to the making of the less costly, less complex, less remembered machines that poured from the Ford plants around the world. And for a simple reason: the production lines required a limitless supply of parts that were exactly interchangeable.

The original Model T had less than 100 parts while a modern car has over 30,000 (and a 787 has over 2 million!).

One of the most amazing applications of precision in the modern world is the manufacture of jet engines. Reading The Perfectionists gave me an appreciation for how incredible they are. Despite being open at both ends, they reach many multiples of atmospheric pressure inside. Furthermore, they reach temperatures higher than the melting temperatures of the alloy the blades are made of. Oh, and the turbine blades need to be a single crystal (no grain boundaries) in order to have sufficient strength. Winchester rightly calls jet engines, "beasts of extreme complexity bound up within a design of extraordinary simplicity":

Although a modern jet engine is, upon close inspection, a thing of the most fantastic complexity, it is easy to believe this is not so. Its exterior cowling is so clean and smooth; the fan blades at its open mouth turn with such slow elegance; the sounds it emits, even at full throttle, have such a sonorous harmony about them, that it is tempting to imagine all is the purest simplicity within. In fact, once the covers are removed, everything inside is a diabolic labyrinth, a maze of fans and pipes and rotors and discs and tubes and sensors and a Turk’s head of wires of such confusion that it doesn’t seem possible that any metal thing inside it could possibly even move without striking and cutting and dismembering all the other metal things that are crammed together in such dangerously interfering proximity. Yet work and move a jet engine most certainly does, with every bit of it impressively engineered to do so, time and again, and under the harshest and fiercest of working conditions.

The part where the bulk air is hotter than the melting point of the turbine blades is dealt with by precisely placing holes so there’s an ultra-thin laminar layer of cooling air directly over the blade:

if the placing of all these pepperings of minute holes is correctly achieved, with some holes on the blade’s leading edge, some on its chubby little body, some along the trailing edge, then this cool air will form an unimaginably thin film of comforting relative frigidity, wrapping itself around the blade and coating its whirling surface like a silvery insulating jacket. It is this, then, that allows the blade to survive the blistering heat of the onrushing fuel-air mixture, which the combustors have just set alight.

The part where blades are grown from a single crystal uses a "pigtail" method (which doesn't sound too far off of alchemy to the uninitiated) and proprietary annealing conditions:

poured into a mold that has at its base a little and curiously three-turned twisted tube, which resembles nothing more than the tail of P. G. Wodehouse’s Empress of Blandings, the fictional Lord Emsworth’s prize pig. This “pigtail” is attached to a plate that is cooled with water, and the whole arrangement, once it is filled with liquid metal, is slowly withdrawn from the furnace, allowing the metal, equally slowly, to solidify.

... And through this magic of metallurgy, the entire blade then assembles itself from the one crystal that makes it along the pigtail, and ends up with all its molecules lined up evenly.

Another amazing application of precision in the modern world is the manufacture of computer chips. In 2015, over 14 trillion transistors per second were made, and they are unimaginably tiny:

The Skylake chips made by Intel at the time of this writing have transistors that are sixty times smaller than the wavelength of light used by human eyes, and so are literally invisible (whereas the transistors in a 4004 could quite easily be seen through a child’s microscope).

The state-of-the-art process for this is EUV photolithography. It is a painstaking process (also discussed in Material World above):

IT TAKES THREE months to complete a microprocessing chip, starting with the growing of a four-hundred-pound, very fragile, cylindrical boule of pure smelted silicon, which fine-wire saws will cut into dinner plate–size wafers, each an exact two-thirds of a millimeter thick. Chemicals and polishing machines will then smooth the upper surface of each wafer to a mirror finish, after which the polished discs are loaded into ASML machines for the long and tedious process toward becoming operational computer chips. Each wafer will eventually be cut along the lines of a grid that will extract a thousand chip dice from it—and each single die, an exactly cut fragment of the wafer, will eventually hold the billions of transistors that form the nonbeating heart of every computer

The Perfectionists covers plenty of topics that I haven't touched on in this mini-review, but I'll wrap up this section with this quote from Winchester on the current state of precision:

Where precision once employed small machines to construct big things, it now employs big machines to create, or to detect, tiny ones.

Paper

I have read and enjoyed a book by Mark Kurlansky before (Salt, reviewed here). Paper is a product I use, an industry that I've had as customers in the course of my job, and even something I've tried my own hand at making. So Kurlansky's book Paper was a logical choice for a longitudinal view of a single industry to fit into my reading theme for 2024.

One of the first things I noticed is that he has a perspective on technology that is opposite to Marshall McLuhan:

Studying the history of paper exposes a number of historical misconceptions, the most important of which is this technological fallacy: the idea that technology changes society. It is exactly the reverse. Society develops technology to address the changes that are taking place within it.

Paper (as distinct from papyrus, parchment, and amate) was invented in China (during the Han dynasty, c. 105 A.D.) and diffused out to the rest of the world. In Asia, paper found many uses beyond writing, including fans, lanterns, and the walls of houses.

If the Chinese and Koreans had brought only papermaking to Japan, it might have had little long-term impact. But they brought an entire paper culture—written language, Buddhism, Confucianism, calligraphy, painting, and even bureaucracy. As in China, the government in Japan began to demand ever more paper. Every family was required to register births, marriages, and deaths with two copies—one for the government and one for the family.

Before paper came to the Middle East and Europe, there was papyrus and parchment. The latter was invented in Pergamum and the Romans started using it for codices in the 1st century BC. Parchment was more durable so it didn't disappear once paper became available, but it was very expensive: it took over 200 sheep to make enough parchment for 1 Bible.

Although today when we think of paper, we associate it strongly with wood pulp, this is a relatively recent development. For most of its history, paper was made from bark or from rags; wood is only ~50% cellulose, compared to 90%+ for cotton rags so it is a more intensive process to make paper from wood pulp.

Here's a summary of the geographic spread of paper mills as recounted in Paper: There was a paper mill in Baghdad in 794 (there was already one in Samarqand prior to this, demonstrating the movement of this technology along the Silk Road). Notable early European mills were in Xativa, Spain and Fabriano, Italy; Fabriano pioneered watermarks and a few other innovations (drop hammers, animal-based sizing (sizing doesn't refer to the dimensions but to surface treatments to make it better for writing on), wire molds). The first paper mill in America was the Rittenhouse mill in Philadelphia area in 1690, almost a millennium after Baghdad.

Paper mills required water for two reasons: power (driving water wheels) and also for making the pulp. The water needs to be clean (an old guideline was that trout should live in the stream) so that the paper is of good quality and not discoloured.

Even in early mills, there was a division of labour, between a "vatman" (drawing the paper slurry out of a vat) and "coucher" (placing the sheets to start drying):

A vatman and a coucher were expected to make a sheet of paper in thirty seconds, and could make between two and four reams of paper a day. Afterward, there was still pressing, drying, sizing, and finishing—usually hand-rubbing with a polished stone—to be done, but the type and quality of the paper had already been determined by the selection of rags, the making of the pulp, and the thirty critical seconds that had passed between the vatman and coucher.

As noted, Kurlansky takes the opposite view from McLuhan (i.e. that "staple" media strongly shape society and culture) and instead sees needs in culture and the economy as the driver of new technologies. This comes out in excerpts like this:

Some historians believe that it was because Europe did embrace printing, whereas Asia and the Islamic world did not, that Europe advanced and Asia and the Islamic world receded. But this is the technological fallacy at work again. Exactly the reverse occurred. Europe needed printing because it was bursting with creativity. New ideas in the arts and sciences, as well as in social justice and religion, desperately needed to be expressed and disseminated. The Chinese and Muslim eras of innovation were mostly behind them. They were societies in decline and didn’t really need printing, which is why the Chinese, who had learned how to print, even with their impossible writing system, did not use it very much.

So in his view an expanding need for paper for everything from laws and bureaucratic records, to maps, sheet music, and later, books and newspapers, drove innovation in printing and paper-making rather than the availability of these new/improved technologies facilitating creativity in other endeavours. Personally, I think there's feedback in both directions between technology and society, but probably incline a bit more to the McLuhan side of this debate.

Getting a working printing press took more than one innovation:

Gutenberg introduced various innovations. He developed an ink for metal printing, which had not previously existed in Europe. The mold he used for casting, the matrix, was probably his own innovation, and it allowed him to make as many identical pieces of type for each character as he needed.

Speaking of Gutenberg, I thought Kurlansky gave the Reformation short shrift. It only got five pages in a book about the impact of paper and printing. Here's some of what he had to say about it:

It would be closer to the truth to say that the printing press was the child of the Reformation. The Reformation was the first movement to use printing to spread its propaganda and was a major reason why printing was invented where and when it was. After all, Europeans had known for a long time how to build a press, how to carve metal, how to cast lead, how to ink and print a carved image, and they might have started printing with moveable type at any time. It is not a coincidence that Germany, seething with unrest and new ideas and an appetite for change, was the place where printing was invented.

Having an affordable, even disposable, medium opened up a lot of new possibilities. This aligns with what the previous books in this post had to say about materials needing to be plentiful and affordable to truly realize their usefulness:

Paper opened up the possibility of the sketch. Renaissance artists sketched out their work before they drew, painted, or sculpted it—or, in the case of Albrecht Dürer’s woodcuts, carved it. This new ability to not only plan but toy with ideas raised their art to a level not known in the Middle Ages.

The printing press leapt ahead of the paper-making technology of its day, so that the supply of paper (or rags to make it) couldn't keep up:

Machine-made books and handmade paper were a tough combination. From the fifteenth century, when printing was invented, until the nineteenth century, when machine-made paper was developed, purchasing enough paper was the greatest problem confronting the book-publishing industry.

British newspaper circulation was almost 30 million by 1820. Rag-based paper couldn't keep up (most paper in Europe was made from rags into the 19th C.). So the connection between paper mills and press barons wasn't a coincidence as the supply of paper was a limiting factor for publications.

The demand for paper was increasing before wood pulp process was discovered and commercialized, which is one point in favour of Kurlansky's view that demand in society drives technological breakthroughs more than new technologies shape society. He credits the idea for paper from wood pulp to Réaumur and his observations of wasps’ nests.

There are now multiple pulping processes such as the sulfite process and the Kraft process. Here is a description of modern paper mills:

A paper mill is, first of all, no longer a mill at all. It does not derive its power from a paddle wheel in an adjacent river, though it is still always located by a river because it needs water for papermaking. The Fourdrinier machine conceived of in the eighteenth century is still in use, but now it is powered by electricity and very large and very fast.

Kurlansky also notes that handmade paper hasn't disappeared:

Technology seldom eliminates old technology. It only creates another alternative. When paper became an industrial product, it was not the end of handmade paper. Handmade paper is still being made, because there are still people who want it, even if it costs considerably more. There are also people who will pay more for linen, rather than wood, paper. But most paper today is made from wood on huge machines.

There was a quote from Diderot that I thought was nicely related to the theme of this post and the series it's part of:

Let us at last give artisans their due. We need a man to rise up in the academies and go down to the workshops and gather material about the arts to be set out in a book, which will persuade artisans to read, philosophers to think on useful lines, and the great to make at least some worthwhile use of their authority and their wealth.

This quote and the following one also provide a good segue from this current theme/series, to the next one I'm planning (on knowing) as one of the things I've learned from this reading is the crucial role of knowledge getting applied to industrial production:

Essentially, he [Vannevar Bush] was addressing the same issue that Diderot had addressed 190 years earlier: as the accumulated knowledge of humans gets ever greater, won’t we reach a point where it is too much to access, too much to sift through?

It didn't fit in anywhere above, but I'll mention that Paper describes the same typical Chinese industrial strategy as Material World: import raw materials (and energy), produce far above domestic needs, export surplus.

Interlude

“Terrifying?” Ciriaco rumbled. “Why?” Espira spread his hands. “When you step back from it, war is about deliveries. We deliver ships and men with the appropriate equipment to the same place at the same time, with their guns all pointed in the same direction.”

This quote from The Olympian Affair, a steampunk novel by Jim Butcher, is about how good logistics is dual-use (i.e. has military applications). This very much fits the current geopolitical context that prompted me to read about supply chains and strategic industries—in early 2025 even moreso than a year ago.

In this interlude, I wanted to step back and look at the big picture. The benefits of the industrial mode of production hit home for me when I was browsing in a fabric store with my wife while I was in the middle of reading some of the history of the Industrial Revolution (I think it was The Perfectionists that I was in at the time, although it may have been Paper). I had the realization that in this one store in one small Canadian city, there were enough bolts of fabric to comprise a king's ransom if you went back just 250 years (Cartwright’s power loom, which was originally water powered, was patented in 1785 and mechanized weaving; spinning was already mechanized at this point).

However, I don't want to overlook the darker aspects of industry. One of those is safety (although this has gotten way better over the past 40 or 50 years). This aspect is illustrated in a really gripping and poignant way by a show I watched on Netflix last year called "The Railwaymen". It was about the Bhopal disaster. Here are a few notes about it:

- First episode sets up an effective contrast between the railway stationmaster who cares about fixing things (promptly replacing a communication line that was stolen for scrap copper) and the chemical plant management that's fine with letting a lot of things slide

- It reminds me of the Halifax Harbour explosion heritage minute and also the post I wrote about Unstoppable

- Safety deficiencies at the plant: flare not working (for 3 months!), gauges reading incorrectly, insufficient training (workers didn't know to blind off certain pipes when they were being flushed to prevent water from mixing with reactive chemicals), no lockout/tagout procedures or even clear/basic communication about which parts of the system were offline for maintenance.

- There was a side plot about a serial thief roving the railway network (committing "acts of dacoity"); he's disguised as a cop and has to help with rescue efforts to keep up appearances.

- It's sad, but well-made and well-acted. Quite compelling—you really care about the characters.

Some ethical issues around industrial production are also raised in this song about Fritz Haber. He contributed to the Haber-Bosch process, which is vital for providing enough fertilizer to feed the world, but he also researched chlorine gas as a chemical weapon (but even chlorine has good and beneficial applications, as we've seen above).

Connectography

Connectography by Parag Khanna was a bit frustrating to read because I didn't feel it delved deeply enough for a book-length treatment. Instead, it felt like repetitive examples of a few ideas. Interesting ideas, to be sure, but as I noted in the introduction to this post, you'd probably get as much out of a magazine article or podcast interview featuring the author as you would from reading the book.

Also... it was published in 2016 and I read it in 2024. Obviously, a lot happened geopolitically in that interval. So several trends and predictions in Connectography haven't fared so well. However, others are looking pretty insightful. Actually, I find there's some value in reading books in this genre with somewhat of a lag since you can partially calibrate how good the analysis is rather than being credulous about it all.

The title of the book refers to the geography of connection, and I'll start with some excerpts that summarize some of the key ideas:

Human society is undergoing a fundamental transformation by which functional infrastructure tells us more about how the world works than political borders. The true map of the world should feature not just states but megacities, highways, railways, pipelines, Internet cables, and other symbols of our emerging global network civilization.

The notion of the connective infrastructure layer being more informative than the political layer is one of the things that looked better in 2016 than in 2024/2025 (more on this below), but connective infrastructure is absolutely something to take into account when looking at geography.

In today’s world, territorial boundaries don’t even really capture the geography of borders: Airports may be far inland but contain borders within them, while cyber-security forces patrol technology infrastructures that stretch far across borders. Even if political borders remain physically robust, the world has still become more borderless as countries eliminate extraneous visa requirements, currencies are exchangeable in real time at ATMs, content from almost anywhere can be accessed online, and the cost of phone calls drops to zero

Borders have gotten a lot more fractal.

Forces such as devolution (the fragmentation of authority toward provinces), urbanization (the growing size and power of cities), dilution (the genetic blending of populations through mass migration), mega-infrastructures (new pipelines, railways, and canals that morph geography), and digital connectivity (enabling new forms of community) will demand that we produce maps far more complex.

Global megacities were growing in influence and national governments were weakening in influence.

Whether you are awake or asleep, scarcely a moment of our daily lives—sipping morning coffee, driving a car, talking on the phone, sending an email, eating a meal, or going to the movies—doesn’t involve global supply chains. And yet as universal as they are, supply chains are not things in themselves. They are a system of transactions. We do not see supply chains; rather, we see their participants and infrastructures

I was hoping the book would go into more detail about the working of supply chains, as that was the reason I included it in the reading I did for this post and this theme.

One of the clearest statements of the theme of Connectography is that,

Each road, bridge, tunnel, railway, and pipeline rewrites the functional code of the countries it crosses,

Another theme that needs to be noted is a central metaphor of "tug-of-war" replacing war war:

Tug-of-war is where geopolitics and geoeconomics come together. War among states is declining while war over supply chains is rising. Tug-of-war, however, is fought not over territory but over flows—of money, goods, resources, technology, knowledge, and talent. These flows are like the rope in tug-of-war: We compete over them, yet they connect us.

The way I'm going to organize the rest of this mini-review is by looking at parts that have aged well versus parts that haven't, and then sharing some miscellaneous points that stood out or are useful information.

The perspective that Connectography is written from is optimistic in an end-of-history way, technocratic in a way I consider typical of the EU (although Parag Khanna is an Indian-American), and bullish on China (and Asia more generally). It has some overlap in tone and general outlook with Dawn of Eurasia by Bruno Maçães (which I reviewed here). It contrasts heavily with the perspective of someone like Peter Zeihan, who is bearish on China (for demographic reasons among other things) and has been predicting a pullback of globalization.

And, well, between the Covid-19 pandemic, the war in Ukraine, and current tariff disputes, globalization isn't looking as strong as it was in 2016. So let's consider some of Khanna's points with the benefit of 8 years' worth of hindsight:

- He trumpeted the decline of significant interstate conflicts since the end of the Cold War, but that is less true since 2022. He also writes at one point that, "almost nobody believes World War III will take place over Taiwan" but this perspective is far less universal now (though hopefully still correct!).

- Here is part of his argument for how financial ties make war less likely than in the past:

But today’s robust flows of global investment among friends and enemies—“frenemies”—further highlight how we have shifted from a Westphalian world to a supply chain world. The world’s leading powers have become financially integrated, with investment linkages as important as trade relations. This comes in the form of both the trillions of dollars of assets invested in each other’s currencies and equities and the tangible, productive capital—factories, real estate, banks, agriculture—they have bought and built inside others’ territory

- Although this quote made me say "uh oh" when I read it:

As the supply chain researcher Barry Lynn writes, “Our corporations have built the most efficient system of production the world has ever seen, perfectly calibrated to a world in which nothing bad ever happens.”

- Khanna mentioned the Greenland independence movement. When I read Connectography last year, that stood out to me as something that hadn't gone anywhere since he wrote the book. But now the future of Greenland is very much in the spotlight, so I'll count this as something that aged well to have even been on his radar in 2016.

- He approvingly notes that "China seeks to emulate Germany more than it does America", but in the past few years the shine has really come off of the German economic model (in fact, I just recently finished reading a book about this called Kaput, that I expect will make its way into a future post).

- Similarly—and this was not unique to Khanna in the previous decade—he admires China's greater capacity than the United States to march in a single direction:

Do Washington politicians, Wall Street bankers, Texas oil companies, and the other players on America’s team act like a single, unified being whose whole is greater than the sum of its parts? Or does China do it better?

- Personally I feel that jealousy over central control is so 2016 and strongly agree with this tweet about the USA being pretty dynamic, in spite of (or perhaps even because of) the chaos of their political process.

- Continuing on the Chinese theme, he favourably mentions projects to extend influence by developing infrastructure, namely the Belt and Road corridor across Eurasia and the "String of Pearls" ports in the Indian Ocean. Regarding the former, he writes that,

Rail transport is faster than shipping and cheaper than flying, eating away at shipping’s leadership in volume and airfreight’s in value. In 2012, only 2,500 containers were transported by rail from China to Europe, but this is predicted to grow exponentially to up to 7.5 million containers by 2020 (still about one-tenth of Europe-Asia oceanic trade).

- These are topics I've looked into before. I don't think it's credible that cross-Eurasian rail is going to be taking a big bite out of inter-continental shipping anytime soon. A Neopanamax vessel can carry something in the ballpark of 20x a train, per numbers in this post. And when I checked a couple of years ago while writing this post, the land port of Khorgas (China's westbound rail terminal), had an annual cargo volume of only 0.5% of the port of Shanghai (the largest in the world, to be fair). On the port strategy, ports in the Indian Ocean that China had invested heavily in as part of the "string of pearls" strategy were not getting much traffic when I checked while writing this post in 2021. Also, let’s check in on how Myanmar, Sri Lanka, and Pakistan (the countries where these ports are located) are doing, shall we?

- Another excerpt that events have certainly intruded on is this one:

Pipelines reconnect feuding siblings and introduce tug-of-war dynamics where otherwise war itself would be the main option. The more pipelines that directly connect Russia to Europe, the more Russia will ensure supply to meet European demand with no reason to choke it off.

- There's a background assumption that technocratic supranational aggregation is the endpoint that everyone is or should be moving towards:

Geopolitical evolution should be measured by this progress toward aggregation: Europe today is both the most legally devolved and the most supranationally integrated region,

- One of the drivers of advancing globalization according to Khanna is cheap money. I mentally noted as I was reading that the days of cheap money/near-zero interest rates might be coming to an end as Boomers have retired and started drawing down their savings.

- I'll end these bullet points with one prediction (i.e. the uncertainty of the future and possible American retrenchment) that was pretty decent:

We also need a world of mutual connectivity rather than geopolitical hierarchy precisely because we cannot be sure of any power’s or region’s fate ten years hence. America could become less interventionist as it leverages its energy wealth to upgrade and invest in its own hemisphere. Europe could suffer political stasis and insularity as a result of its economic malaise. Asia could be beset by strategic rivalries that derail its spectacular growth.

I think the hits and misses listed above all have a common thread. Like Dawn of Eurasia, the analysis in Connectography seems suited for the prevailing international relations (IR) conditions in the 3 decades from 1990 - 2020. There's an excellent description of IR Neorealism in this blog post about a video game that lists a series of conditions: interstate anarchy, hegemony, balance of power, international law (possibly seen as a mask for imperial power). I think there's a real possibility that the world is shifting into a balance of power mode (although I wouldn't call it a foregone conclusion). This quote about security provision versus infrastructure provision, for example, is something that I think is highly dependent on the prevailing IR conditions:

Americans have long presumed—largely correctly—that “security” is the most important global public good and that the world looks to America to provide it. After World War II, the U.S. military umbrella over Europe allowed it to peacefully integrate into the world’s largest economic region. Today America’s military “pivot” to Asia deters Chinese aggression, but China diverts that energy into building more infrastructures with its neighbors (and beyond) to more deeply bind them to China, something America cannot deter. To the contrary, infrastructure provision—and the connectivity it represents—have become global public goods on par with security. They are things countries desperately want, and China is their leading provider. With most of the world’s future infrastructure yet to be built, China is out to become the world’s largest infrastructure exporter. Many countries still want the American military protecting them, but even more want China’s infrastructure finance and low-cost telecom equipment.

To wrap up my mini-review of Connectography, here are a few more points that I thought were interesting or useful for reference:

- He mentions Metcalfe's Law, that the value of a network goes up with the square of the number of connected nodes.

- The book had more about Special Economic Zones (SEZs) and less about the mechanics of supply chains than i expected. This includes lots of examples of specific global nodes, such as the Dubai success story.

- Good quote about cities and their function:

Cities can be thought of as ancient social technology, infrastructures that aggregate people into a dense and productive division of labor. But humanity’s rapid urbanization only means that people are moving into cities, not that the cities are prepared for their arrival.

- On infrastructure investment:

Infrastructure investment is much stickier than factories, for roads and railways cannot be uprooted and sent somewhere cheaper.

- On a finishing note, the reality of global supply chains today:

The more you try to untangle global trade, the more quantum it becomes. The path by which so many even simple products are put together is so complex that there is no clear answer as to where something is “made.” Manufacturing supply chains began to unbundle almost fifty years ago,

Something I wrote on Facebook with regards to Canada's vulnerability to a trade war due to our dearth of connective infrastructure fits well with the themes of Connectography, so I'll share it here too:

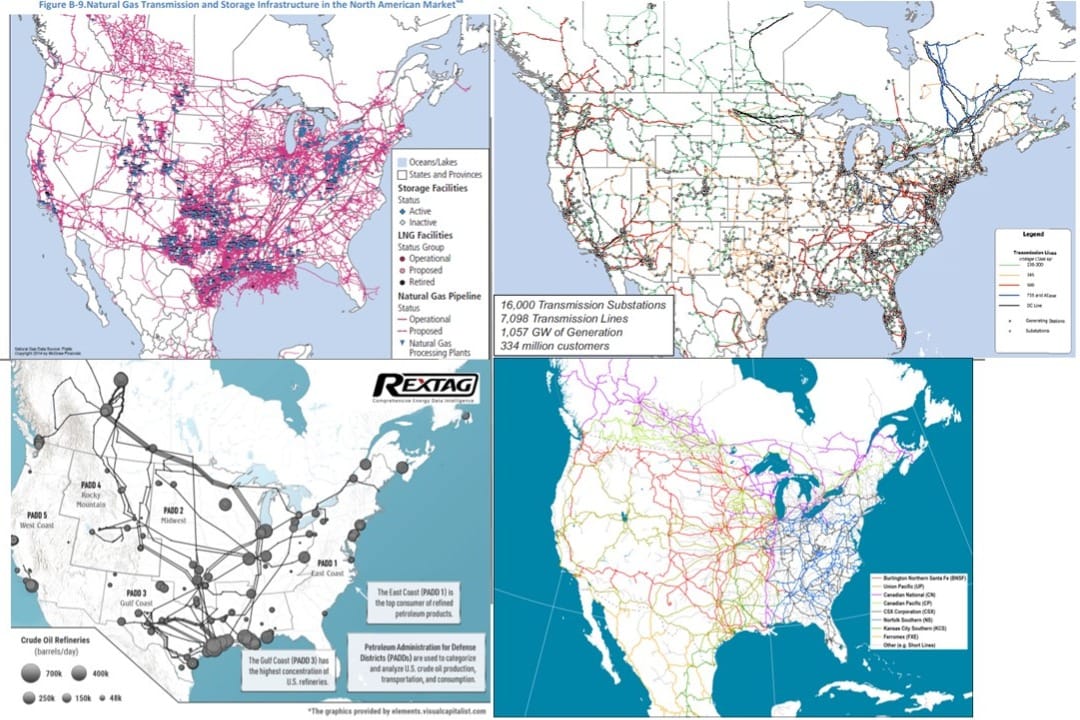

Something that's very salient is our dearth of east-west infrastructure for moving goods to domestic markets across the country or to tidewater for access to international markets that aren't just the US. The following maps I found show infrastructure networks in North America for gas pipelines, transmission lines, oil pipelines, and railways. For some of these there are outright discontinuities within Canadian borders while others just aren't very robust in places (e.g. north of Lake Superior, across the Rockies, and between Quebec and Atlantic Canada). Let's look at a few examples:

1) Rail - Passenger rail gets a lot more attention from the public, but there are other ways for people to get around. There aren't really many viable alternatives when you want to move kilotonnes of wheat or potash. The rail network has more density within Canada than many other types of infrastructure but we've seen in recent years that it has some problematic bottlenecks and chokepoints. Remember the #shutdowncanada protests when a blockade in Eastern Ontario cut off cross-country shipments for a week or two?

2) Oil - The important hub of Canada's chemical industry in Sarnia is supplied (it needs oil not only for energy but as a feedstock) by Enbridge Line 5, a pipeline that runs through Michigan (whose governor has threatened to shut it down before) despite largely carrying Canadian oil to Canadian destinations. The Energy East project cancelled in 2017 would have filled a vital infrastructure gap in terms of giving access for Canadian oil to Eastern Canada (not sure about Sarnia specifically) and export markets without dependence on the US. Our current bargaining position would be stronger if it had gotten built.

3) Gas - In the map of gas pipelines there are few connections to the coast and thus few opportunities to export to international markets. As far as I know, the first major LNG export terminal will begin operation later this year; along with it, any others in the works are also on the West Coast. When the Ukraine War broke out some European leaders inquired about sourcing LNG from Canada to replace gas from Russia. Our PM infamously said he couldn't see a business case for it. There are no LNG export projects in the works on the East Coast. So the only export option at the moment is to the US (and not even the whole domestic market is connected to Canadian sources of natural gas).

We've been here before in our history, where improving our infrastructure has been a means to shore up our sovereignty and national unity. The Rideau canal was built starting in the 1820s to provide a linkage between Kingston and Ottawa (and onwards to Montreal via the Ottawa River) that didn't run right along the US border. Later, in the 1880s, the construction of a transcontinental railway was a crucial condition of British Columbia joining Confederation.

From the Garden to the City

From the Garden to the City by John Dyer is a study of technology in the Bible, followed by some discussions of present-day applications. I included it in this project to cover the moral and ethical angle. The applications in the book focused (though not entirely) on digital technology, but I'm going to try to relate them to industry and supply chains.

To begin this mini-review, here are a few excerpts that summarize some of the main points:

most people assume that technology is simply neutral, and that all that matters is how we use it. I plan to upend this notion with two key ideas. First, as we study the Scriptures, we will find that, theologically speaking, technology is a God-given good. And second, we will discover that, practically speaking, technology is never neutral.

Whenever we use tools, from shovels and books to phones and virtual reality, regardless of whether we use them for good or evil, the act of using them forms us physically, mentally, spiritually, and relationally. The problem with thinking of technology as neutral is that doing so often makes us miss all the other non-neutral ways its presence in our lives affects us.

Our goal then is not simply to condemn technology as bad, neither is it to naively embrace every new gadget. Nor is it to glibly assume that because we are using a tool for good ends, nothing else matters. Instead, we are to carefully examine each new tool, device, and service, noticing the goodness of God in giving us such powers, and yet asking ourselves not only how we can use it but also how using it might transform us in the process.

The last line of the previous excerpt is probably the most repeated point in From the Garden to the City: that we need to be mindful not only of the ends to which we direct technology, but also of the effects that using it has on ourselves. Here are some of the reiterations of this point:

whenever we use a tool, whether it be a shovel or a phone, three powerful stories unfold: how we shape the world with technology, how technology shapes us, and how we see the world through technology

Indeed, as John Culkin, a student of Marshall McLuhan, wrote, “We shape our tools and thereafter our tools shape us.”

Or,

The world feels the spade, but we feel the handle.

A shovel is a simple example, but the same principle applies to our apps and devices. Where using the former can develop calluses on our hands and muscles in our arms, the latter do something similar to our brains:

when we perform a mental task repeatedly, our neural pathways rewire themselves to become better at that task.

I don't want to spend too much time on what Dyer has to say about digital apps and devices as that isn't the focus of this series I'm writing. However, it's such a ubiquitous part of contemporary life and he says some things that are challenging and worth reflecting on so I don't want to pass over this entirely. Some examples that expand on the previous excerpt are the way the implicit effect of Twitter is "increasing our ability to consume short, disconnected sentences" or for social platforms in general they get us "thinking about events throughout the day in terms of how post-worthy they might be, rather than reflecting on the meaning of our lives". Or when it comes to streaming, he writes that, "We don’t want to err into determinism and argue that streaming services made anyone do anything, but neither do we want to err into instrumentalism and say that the change in medium didn’t matter or had no effect. ... When our devices change, our culture changes" (more on the determinism vs. instrumentalism question below). An example of this might be that due to the personalization that streaming offers we have fewer and fewer references/allusions in common with our neighbours. And a great parenting tip related to this topic is to teach kids to be more than passive consumers:

We’ve attempted to instill in them the idea that screens are for making, not just consuming, and they each have learned to optimize their screen usages for creation.

Before getting into the application to industry, I'll take a brief detour through some definitions and debates. Firstly, here are some definitions he gives for technology:

If you’re keeping track, this means that “technology” now has at least four different meanings: (1) the skill of making things, (2) the study of the skill of making things, (3) the tools used to make things, and (4) the things made with these tools.

The main debate covered is between instrumental and deterministic perspectives on technology:

- Instrumentalism: "technology is merely the instrument of the person using it. The tool itself is neutral in that it is interchangeable with any other tool with no effect"

- Technological determinism: "technology is an unstoppable power that has become the driving force in society"

In one of the excerpts above, Dyer quotes a student of Marshall McLuhan's. In fact, in multiple places he makes reference to the ideas of McLuhan or those who built on them (e.g. Neil Postman, who pointed out that technology is like an ecosystem and adding a new form changes the balance). The views of this school would be more towards the determinism side; in my review of Understanding Media by Marshall McLuhan, I explained the well-known phrase, "The Medium is the Message" as emphasizing that "the impact of the content carried by any particular form of media is negligible compared to the impact of the structure of the prevailing media on society" (and what McLuhan calls media is broader than how most people use the term, encompassing any communications technology and even transportation). I think Dyer is aiming for a via media between these two perspectives, but is using references like these to push back against a strictly instrumental view that technology is neutral and the only moral question is what you use it for. Instead, you should consider the way values are implicitly embedded into the things we make by the problems they solve; that is, even what we see as a problem needing to be solved is a value judgement. For example (and these are his examples, not my own), cars allow for flexible individual travel and phones allow for being constantly connected. They're an embodiment of valuing these things. Dyer's take on the printing press and the values it contains stood out to me as being directly opposed to Kurlanksy's view discussed above (i.e. that society shapes technology rather than technology shaping society):

the medium itself carried an innate message: information should be freed from authoritarian control. This led to major cultural shifts including the scientific revolution, the Protestant Reformation, and the creation of democratic nations like the United States. This new level of access to information also brought with it radical new ways of thinking embedded in the medium itself.

I also really liked this scriptural take on "the medium is the message" (or one could say, "the Mediator is the Word"):

We have seen that God has used a variety of different forms of mediation to communicate to his beloved children, from an audible voice to a flaming bush to the written word. We have even seen that God restricted the use of carved images in Israelite worship in order to communicate that he was not like other gods who could be contained by a block of wood. But when God wanted to communicate the depth of his love and grace, he chose the ultimate medium: the eternal Son of God became a son of man.

We'll now look at what John Dyer says about industry. Something I've become more aware of over the past couple of years as I've been deliberately thinking and reading about industry is basically what he says here about "sociotechnical systems"; it's not sufficient to plop down the right equipment in the middle of nowhere but rather modern manufacturing is a whole ecosystem that depends on supply chains, education and training of a skilled workforce, a large variety of supporting businesses, finance, etc.:

“Technology as manufacturing” includes the vat holding the molten steel for our cars, the robots that put together our phones, and even the complex sociotechnical systems that need to be in place for the factories to operate. This includes everything from the people running the machines to the electrical grid powering the plant to the legislation that regulates the industry.

Technology is dependent on other technology. Cars need roads (and refineries), cellphones need towers (and batteries, and towers, etc), even the most basic agriculture benefits from having pottery for storage and cooking. It’s a stack. Likewise, the following point definitely came up other books discussed in this post (especially Material World and Connectography):

As our tools grow more and more complex, the network of people and machines needed to make them grows as well, sometimes spanning multiple continents.

In From the Garden to the City, Dyer offers a rubric for evaluating technology and how we use it. If it was just the first row, it would reduce to the "Instrumentalist" perspective, where the only moral/ethical consideration is what it is used for. However, as I've mentioned he emphasizes throughout the book that we also need to think about unintentional effects, such as how using a particular technology shapes ourselves or the culture around us, and this is where the second row comes in. Both rows have a positive and negative potential.

|

|

Positive |

Negative |

|

Intentional |

3. Redemption |

2. Rebellion |

|

Unintentional |

1. Reflection |

4.

Restoration |

Here is part of the explanation that goes with this rubric:

Our intentionally good uses of technology are often redemptive, while the unintentionally good things that sometimes come with a new tool can be a reflection of the mystery of God’s image. On the one side, the intentionally evil things we do with technology are part of our rebellion against God, and the unintentional side effects that come with technology make us long for restoration.

When I thought through applying this rubric/tetrad to the industrial mode of production, it occurred to me that it's sort of a meta-technology. That is, a technology (including both physical equipment and "sociotechnical" aspects) for making other technologies. (Supply chains are also kind of a meta-technology that allows for not being vertically integrated or co-located.) So it's at a higher level of abstraction.

So with this in mind, applying the above rubric to industry, for the first row I'd ask a question like whether the product is more beneficial than harmful? For example, cheese and paper vs cigarettes and chemical weapons. However, even things that are generally beneficial can be put to bad ends (e.g. gluttony), and some things that are often harmful can still have some positive uses. I think I mentioned chlorine earlier in this post, which was invented as a chemical weapon but has found widespread use in drinking water disinfection. Cases like that probably come with a duty of care to do due diligence on one's customers, though.

Moving to the second row, industry has a lot of unintentional effects—a mixture of positive and negative:

- It provides good jobs (even a lot of factory jobs early in the Industrial revolution were good relative to the alternatives), which drives urbanization and migration, which are also a mixture of positive and negative.

- Pollution (due to having more concentrated production than artisanal mode) and safety are things that have been partially redeemed